Dust Control and Collection

Tissue, towel and paper manufacturing and converting produces a significant amount of airborne dust. Paper dust, if allowed to reach higher concentration, is a nuisance, fire and health risk. Dust Control and Exhaust Systems have been proven as the best way to contain and remove the dust from the machine room. The primary function of a dust control system is to cut the amount of airborne dust particles to improve the environment for the employees, prevent operation and maintenance problems that lead to poor sheet quality and frequent downtime for cleaning and lower dust accumulation on the flat surfaces.

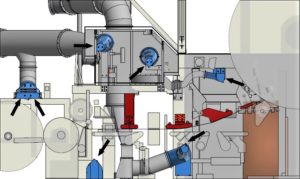

AIRTHERM offers custom Dust Control and Collection Systems for new and existing paper machines and rewinders. An AIRTHERM Dust Control system uses custom pick-up hoods to improve the dust collection effectiveness. Once the dust is in the conveying air, it is removed from the airstream before exhausting either to the atmosphere or back into the building. AIRTHERM offers three types of dust collectors; dry pulse jet cartridge or bag filter house, a dry rotary drum filter with post filters and a wet venturi scrubber.

Optional vacuum methods, floor treatments, air bars, sheet stabilizing foils, sheet cleaners, material conveying systems, ionization bars and exhaust enclosures for dust containment are available to optimize the control system performance. Isolation valves, static control devices and spark detection and suppression systems are also available for increased hazard protection.

Vacuum Methods – There has been a concerted effort to encourage vacuuming of dust around the manufacturing and rewinder machines instead of using the traditional “blowdown” method with compressed air. Blowing down a machine “launches” a large amount of dust into the air resulting in a cloud that simply sends the dust to settle somewhere else. Using a powerful vacuum system first removes the bulk of the dust from easy accessible surfaces. Tight, hard-to-reach spots can then be cleaned with crevice tools or minimal compressed air pressure to do the job. There are several ways to use vacuum cleaning:

- Dust Collection System Tie In – Floor hood receptacles and vacuum hoses are directly connected into the dust control system with or without a compressed air booster mechanism.

- Independent Vacuum/Broke Handling System – Continuous trim, cookie and broke handling systems are ideal for vacuuming around the machine. These systems offer more suction for conveying and vacuuming than the dust control system. The broke system includes a separator to remove the broke from the conveying airstream and a dust collector for cleaning the conveying air before discharging outside or back into the building.

- Dedicated Vacuum System – Installed strictly for machine cleanup. Systems sized for use on one or two machines (small) or to handle the entire mill with a single unit (very large) are available.

Floor Treatments – Floor mounted collectors come in two different styles:

- Manual – Operators use a manually operated damper to control the exhaust from each floor hood.

- Automatic – Each damper would be fitted with an actuator to automatically control the exhaust from each floor hood. Air Bars are then used to “sweep” the dust that falls to the floor toward the floor hoods.

Air Bars – Strategically placed air dispensers that motivate dust towards a desired collection area. Air bars come in several styles:

- Floor Air Bars – Cross-machine, compressed air or pressure blower supplied pipes with discharge nozzles to gently blow dust toward a floor mounted exhaust hood. The air bars are either manually operated or automatically sequenced on a timed rotation.

- Machine Air Bars – There are always areas within the rewinder where dust can accumulate on a flat surface or critical components. Cross-machine or partial air bars will gently blow dust off these surfaces. These air bars would be automatically sequenced as required to keep the surfaces free of dust.

Sheet Stabilizing Foils – Full sheet width or partial foils; static or dynamic designed to control sheet flutter, floppy edges, sheet spreading or simply an alternative to an idler roll to support the sheet. Sheet Stabilizers have been successfully used to tackle control issues on machines with speeds up to 6,000 FPM and sheet widths up to 240″.

Sheet Cleaners – Includes dynamic stabilizing foils to dislodge the surface dust from the sheet and an exhaust hood to convey the dust laden air into the collection system. Ionization bars mounted upstream of the sheet cleaner can improve cleaning of even the toughest dust deposits.

Material Conveying Systems – Complete systems for handling the waste material from the manufacturing or converting process of tissue, paper, board, film and foil products. Trim, broke, butt rolls, scraps, slabs and rejects are pneumatically conveyed to a final collection and processing point. Shredders, separators, balers and dust collectors are included to match the application.

Ionization Bars – Used for eliminating static charges that hold the dust on the sheet. These bars allow for more thorough removal of dust in the sheet. When combined with a compressed air knife, the neutralizing ions cover a greater distance for even better performance.

Exhaust Enclosures – Custom fabricated enclosures for dust and fume capture are stainless steel, painted mild steel or aluminum and include full width exhaust. The enclosures are single thickness or insulated and include access doors, viewing windows, lighting and sprinkler systems.

Isolation Valves – Flow activated, passive inlet isolation valves are used to protect downstream work areas and processes from exposure to flame and pressure through the inlet duct if a deflagration (explosion) occurs in a dust collector.

Static Control Devices – For longer conveying runs, an in-line static control unit is recommended for neutralizing static charges on broke in the pneumatic conveying system. The unit is mounted upstream of the separator so that trim is neutralized as it passes through the unit and won’t “stick” to metal surfaces.

Spark Detection and Suppression Systems – For an added level of safety, a spark detection and suppression system is available. In general, these systems might not be specifically required by the NFPA or insurance providers, but add increased fire and deflagration hazard protection.

Dry Pulse Jet Cartridge or Bag Filter House – One of the most common and compact types of dust collectors, these fabric filters are efficient and the least costly option for dust collection. The method of cleaning the bags typically differentiates the various models available. A pulse-jet type baghouse can operate continuously for uninterrupted dust control.

Dry Rotary Drum Filter with Post Filters – The primary filtration is done with a rotating perforated drum that is covered with filter media inside an enclosure. The drum removes the bulk of the dust from the airstream, but secondary filtering is required meet environmental codes. The main exhaust fan pulls air and particulate into the enclosure. The clean air passes through the filter media that is covering the rotating drum. Dust and particulate matter remain on the media and are then removed by an arrangement of suction nozzles as the drum rotates against them. The air is further filtered as it passes through two more banks of passive filters before being discharged back into the building or to the atmosphere.

Wet Venturi Scrubber – Designed to bring dust-laden air into close contact with the scrubbing water by means of acceleration and turbulence in a venturi throat. The scrubber is designed for high efficiency and will include a recirculating water system and slurry return. The adjustable venturi includes a manually operated, variable throat mechanism that permits adjustment of the venturi performance. The feature can be used to upgrade collection efficiency or allow for an increase in system capacity or reduction in operating horsepower. Auto venturi adjustment is also available for variable process needs.