Heat Recovery Systems

AIRTHERM Heat Recovery systems come in several styles to meet specific needs:

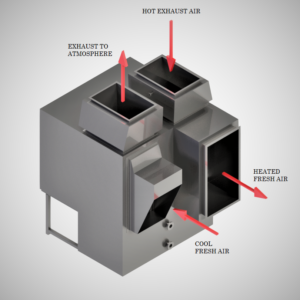

- Air-to-Air heat exchangers to reuse heat from process exhausts to pre-heat air utilized in process supply air systems.

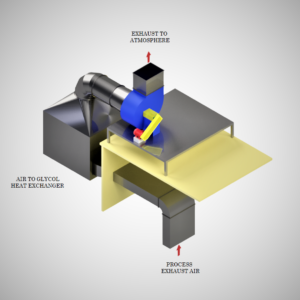

- Air-to-Water/Glycol heat recovery to reclaim waste heat from exhaust systems for use in building make-up air units.

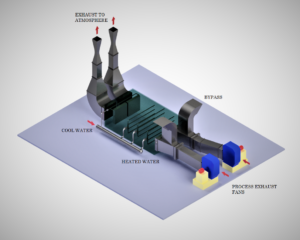

- Direct Spray economizers to reuse high temperature exhaust air to heat water for other processes.

|

Air-to-Air Heat Recovery |

|

|

Air-to-Water/Glycol Heat Recovery |

|

Direct Spray Economizers |