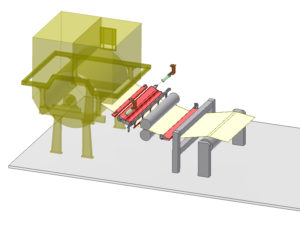

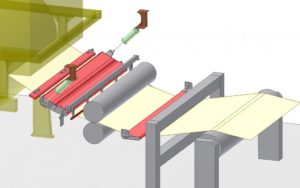

Sheet Stabilization

Full sheet width or partial foils; static or dynamic designed sheet stabilizers are used to control sheet flutter, floppy edges, sheet spreading or simply as an alternative to an idler roll to support the sheet. Sheet Stabilizers have been successfully used to tackle control issues on machines with speeds up to 6,000 FPM and sheet widths up to 240″.

- AIRTHERM Sheet Stabilization systems are designed to support the sheet from the Yankee dryer to the reel.

- Stabilizers can be retracted to allow easier access for operation and maintenance personnel.

- Stabilizers can be “static” and utilize the sheet speed to operate or “dynamic” with auxiliary air supply to ensure proper operation at slower line speeds.

- Sheet spreading can be accomplished to prevent wrinkles leading into the calendar nip or onto the reel; replace Mount Hope bowed rolls.