Paper Machine Hoods

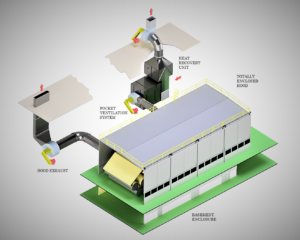

AIRTHERM Totally Enclosed Paper Machine Hoods provide the best vapor confinement and collection of moisture around the drying process. Complete enclosure allows for minimum exhaust airflow and higher humidity levels. A Basement Enclosure is also a key component for minimizing cool air infiltration into the dryer section and controlling the drying environment. Standard and High-Humidity Hood construction is available to meet any machine requirement. AIRTHERM is also able to offer retrofitting of older, open style hoods, to allow for them to become fully enclosed hoods.

The Hood Exhaust System utilizes a specially designed internal plenum to insure the vapor is removed uniformly in both the machine and cross-machine directions. By carefully controlling the exhaust profile, the energy efficiency is maximized while fully containing the vapor within the Totally Enclosed Hood. The Pocket Ventilation System works in conjunction with the hood exhaust to properly ventilate the paper machine dryer section improving the evaporation rate and reducing steam use. Heat Recovery can be used to preheat the hood supply air or to heat make-up air as part of the Machine Room Ventilation System.

Features:

- Modular, easily removable panels for quick access to the paper machine dryers provide solid thermal barrier between the machine room and the drying process.

- Front lifting doors with lifting mechanism (cables, straps, air cylinders or screwjack) and a continuous viewing window and safety devices.

- Telescoping Rear Sliding Doors allow easy access to the drive side of the machine. Doors are quickly removed to allow full access to large areas of the machine for maintenance.

- End Doors and Personnel Doors seal the ends of each hood around the sheet path.

- Large bi-parting swing doors with optional monorails for moving dryer fabrics in & out of the upper portion of the hood.

- Complete walkway systems for maintenance access to elevated machinery.

- Aluminum or stainless steel insulated panel construction.

- Walkable roof panels / walkways with handrails, kickplates, safety gates and caged ladders.

- Structural steel framing with monorails for moving rolls and heavy parts within the hood.

- Hood lighting and complete sprinkler systems.

- Heavy-duty, high-efficiency centrifugal fans with optional corrosion-resistant coatings and stainless steel or aluminum construction.

- Premium efficiency, TEFC motors belt-driven or direct drive.

- Heavy papermill sheet metal ductwork.

- Heat Recovery is used to preheat the Pocket Ventilation air utilizing excess heat that is exhausted from the paper machine hood.

- Field Studies and Surveys are available to help determine whether to rebuild or replace existing systems.

- Repairs, Upgrades & Spare Parts are available on existing systems regardless of the age, condition or original manufacturer.