Pocket Ventilation Systems

AIRTHERM Pocket Ventilation Systems (PV Systems) are custom designed and engineered to optimize the drying processes of paper, board and specialty grade machines with unique and varying requirements.

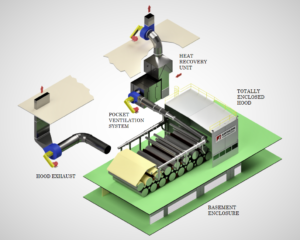

The PV system works in conjunction with the paper machine hood and exhaust system to properly ventilate the paper machine dryer section.

A PV system will improve the dryer evaporation rate, improve the sheet moisture profile, reduce steam use and increase production.

PV Systems are also used to provide heated air to other hood supply equipment such as CM ventilators, air doctors and felt conditioning nozzles.

Features:

- Pocket Ventilators use multiple air discharge slots and holes to deliver tempered air into each pocket and prevent moist boundary-layer air from re-entering the pocket area.

- AIRTHERM Vapor Absorption Nozzles can be utilized to purge the moisture from the return felt fabric before it re-enters the dryer section. The nozzles can also be used to supply heated air to un-felted dryer sections and to the basement enclosure area of the paper machine.

- HT “High Temperature” Impingement Nozzles – a hybrid between a vapor absorption nozzle and an impingement dryer, HT nozzles can be used to deliver heated air to the dryer section. Individual high temperature nozzles (300 – 600 °F) are designed to blow directly on the sheet in a machine dryer section (without felts) to increase the drying rate. Captured paper machine hood exhaust is also recirculated through a burner, like a dryer system.

- Aluminum or steel construction with edge dampers to control sheet moisture profile.

- Cross-machine Ventilators mounted below unirun dryers provide warm air to the sheet during travel between the dryers.

- Air Doctors and Felt Nozzles used to strip the moisture boundary-layer from the dryer felts and condition the felts prior to contacting the sheet.

- Heavy-duty, high-efficiency centrifugal fans with optional corrosion-resistant coatings.

- Premium efficiency, belt-driven or direct drive TEFC motors.

- Standard steam-heated and high temperature, gas-fired ventilation systems designed to boost the drying capacity on heavy grades are available.

- Condensate receivers and steam traps insure proper operation of the steam coils.

- Heavy paper mill construction of the coil housing and sheet metal ductwork.

- Heat Recovery is used to preheat the PV air utilizing excess heat that is exhausted from the paper machine hood.

- Field studies and surveys are available to help you decide whether to rebuild or replace existing systems.

- Repairs, Upgrades and Replacement Parts are available for existing systems regardless of the age, condition or original manufacturer.